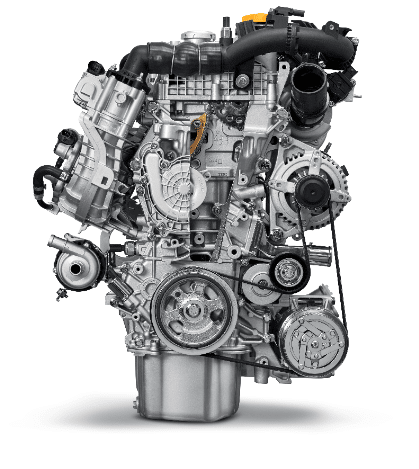

The one hundred-thousandth FireFly Turbo engine (Global Small Engine – GSE Project) was made this week in the FCA Powertrain plant in Bielsko-Biała (Poland), one of the most innovative engine factories in the world and World Class Manufacturing Gold Medal holder since 2012. The one hundred-thousandth engine was a FireFly Turbo 1.0 and, together with the 1.3-litre version, is yet another confirmation of the engineering supremacy of the Group. Not unlike their namesake, the new FireFly Turbo engines are the most compact and cleanest power source currently fitted on Fiat cars.

Currently available on Jeep Renegade and Fiat 500X, the new family of 3- and 4-cylinder FireFly Turbo petrol engines is designed to offer customers a new balance between performance and driving pleasure, while ensuring significant savings in fuel and CO2 emissions compared to the previous petrol engines. Remarkably, 1.5 tonnes of CO2 have been saved by the first 100,000 FireFly Turbo engines.

The FireFly engines are Euro 6/D-TEMP-compliant and equipped with GPF (Gasoline Particulate Filter) for petrol engines. Robustness and reliability of both product and process are tested and guaranteed by 75,000 hours of virtual analysis, 60,000 hours of off-vehicle testing and some five million kilometres driven across various continents.

Their particularity is in their specific architecture that guarantees efficiency, modularity, a high degree of component and production process standardisation, flexibility and openness to future evolutions.